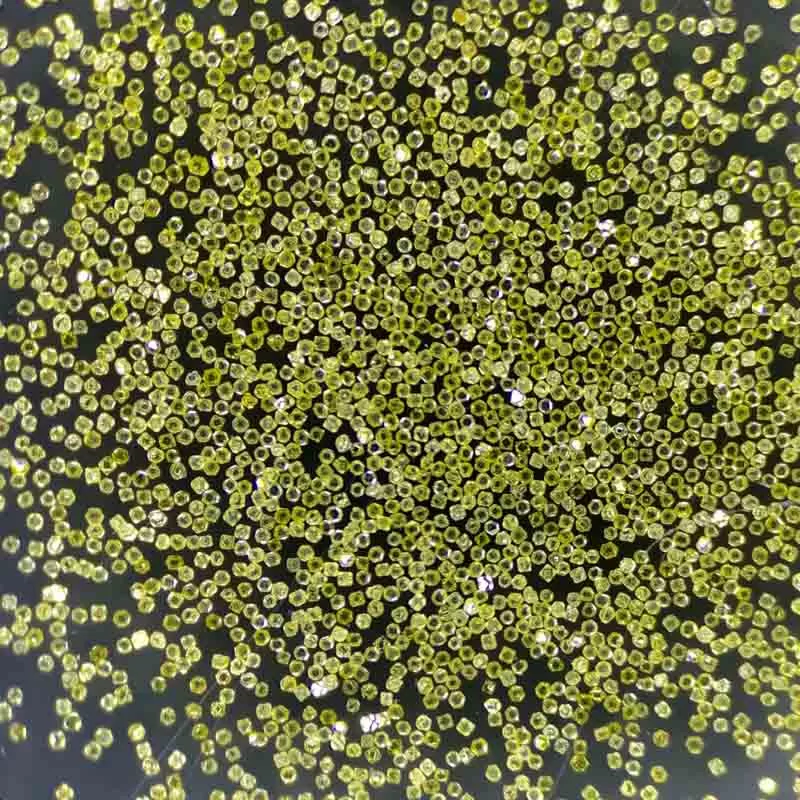

Diamond powder mesh size for polishing ceramic tile

Diamond powder is a fine diamond powder that people use on the final surface when they apply ceramic tiles, to make it shiny and smooth. Almost like a sacred dirt that offers some shine. When we choose the diamond powder for polishing, it matters a lot in terms of the mesh size,in other words, what is the fractionation degree of these power pieces. Size is key here – get it right and your tiles will look fantastic!

Why do Small Mesh Sizes for Tiles Polish?

The mesh size of Diamond Powder plays a significant role in the manifestationantly, smooth polishing and bone powders are shinier. Smaller mesh size indicates smaller pieces of powder. This powder can also make the tile a little more even and glossy as it is polished. Therefore, you must select the proper mesh size when opting for ceramic tile polishing in order to obtain optimal outcomes from it.

What is Mesh Size?

Mesh Size…What does mesh size really mean? Mesh size refers to the number of small holes in a sieve per square inch. Higher mesh size = small hole, and fine powder pieces. For instance, when you have 60 coating diamond powder may be larger than those of a really fine 200 mesh diamond-powder. Understanding mesh size helps you select the appropriate diamond powder for your desired polishing processes.

The Impact Of Mesh On Your Polishing

Higher mesh numbers usually produce shinier tile, but as noted in our previous entry the diamond powder size does influence this. The diamond powder larger the mesh size you use, a finer material it removes from your tile which may be useful in some cases but on the other hand you will have to remove a lot of excessive materials and that would expose more fine adjacent fibers leaving deeper scratch marks. However, using smaller mesh size will remove less material and give a surface cleaner smoother shiny finish. Which makes understanding how mesh size can make or break our polish a little easier to swallow.

Choosing the Right Mesh Size

Before diving into the right diamond powder for polishing, there are a few things that you must keep in mind. Your starting point will be to find out exactly how hard the tile is. Is it as tough a tile like granite, or is the surface softer (ceramic)? Now, consider your desired level of shine for the tile finish. Choose a finer mesh diamond powder for hard tiles such as granite, if you wish them to turn out high-gloss shine. However, if you are working on a softer tile like ceramic then using coarser mesh diamond powder will be beneficial. This way, you have the best results on each type of tile.

The Importance of Mesh Size

The mesh size of Coated Diamond Powder plays a great significance in ceramic tile polishing. This actually helps a little bit in raising enough coarseness to get the shine you want. Plus also can have a big bearing on how the finished surface presents itself, Together with this is many things to do using what mesh size you end up picking. A finer mesh size will, for instance, remove less material from the tile so that it offers a more refined and polished finish than example with coarser mesh size this leaves surface appearance as being polish deficient.

To sum it all up, having the best diamond powder mesh size for your ceramic tiles is something that you need to think about. Hengfeng provides various types and particle sizes of diamond powder according to your different polishing requirements. With our superior diamond powder, your ceramic tiles are perfectly polished to give a shiny and beautiful appearance during installation. Just a little tip about mesh size when polishing tiles for you to take away with!